RAGAGEP stands for Recognized And Generally Accepted Good Engineering Practices.

Specifically, OSHA 29 CFR 1910.119 (D)(3)(ii) states:The employer shall document that equipment complies with recognized and generally accepted good engineering practices.

EPA RMP also refers to RAGAGEP in 40 CFR 68.73:Inspection and testing procedures shall follow recognized and generally accepted good engineering practices.

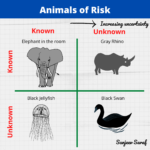

What Constitutes RAGAGEP?

A few sample sources of RAGAGEP are:

- State laws

- American Petroleum Standard (API) standards

- Center for Chemical Process Safety (CCPS) guidelines

- National Fire Protection Association (NFPA) standards

- Industry guidance developed on the subject

- Reports

- Published Recommended practices

- Written company policies and procedures

- Insurance guidance

Not all RAGAGEP are mandatory…they are meant to be consensus codes and standard reflecting industry’s practices for mechanical integrity that have evolved over the years.

The interpretation of RAGAGEP is rather broad making it difficult for organizations to translate the performance-based intent for equipment reliability into functional policies. Is it any surprise then that Mechanical Integrity (MI) is the most widely cited PSM element during the NEP?

What if my facility is not covered under PSM…will RAGAGEP still apply?

Well, I’m not a lawyer but let us think through this issue. The General Duty Clause says that you shall manufacture in a manner that is safe for workers, society and environment. So you tell me…is it a good idea to adopt RAGAGEP even if your facility is not covered under PSM?

For the benefit of everyone, please share RAGAGEP issues you may have encountered in the comment section below.

One Response

Informative post Sanjeev. Thanks for sharing. Good example would be explosion ventilation panels as referenced in the NFPA combustible dust standards, installed on a dust collector to minimize the severity of a dust explosion.