It is hard to imagine but only a few years ago not everything was on the internet. Google was established in 1998 and as search became prevalent, there was an explosion of online for anyone to access.

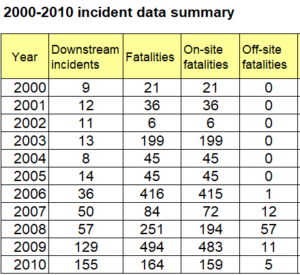

From 2008-2010, I went through exercise of collecting and analyzing incident data from 2000-2010 with help from Dr. Amy Liu. Mostly downstream – refineries and petrochemicals.

The effort was focused strictly on using public resources and so it is not surprising as more publications moved online, you see an increase in number of incidents. By the time we got to 2010, we had pretty good handle on data sources and algorithms to find and classify.

That incident rate of 155 incidents per year or 3-4 incidents per week anecdotally seems right.

Even today the incident frequency remains comparable. Approximately 1 in 1000 years.

Just look at last seven days in December 2020.

4-Dec. Explosion at a water recycling plant in Bristol

Four people were killed in the blast at a water recycling center in Kings Weston Lane, Avonmouth, on Thursday.

4-Dec. Explosion at a refinery in South Africa

Seven people were hospitalized following an explosion at Engen refinery in Durban. Six of the workers were being treated for smoke inhalation and the other injured their hip in a fall while trying to escape the fire.

5-Dec Explosion at gas plant in El Salvador

A gas plant just outside the country’s capital San Salvador went up in flames. There have been no reports of victims or injuries.

8-Dec Explosion at a Chemours chemical plant in West Virginia

An explosion was reported at former DuPont facility.

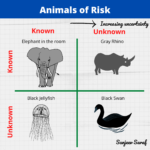

This begs the question, are current process safety practices effective?

Incidents are probably not a good metric to look at efficacy of risk management strategy but let me ask a slightly different question.

In 2021, can the number of incidents drop by an order of magnitude? 15?

Process safety has come a long way since Bhopal disaster but we are far from zero incident facilities.compra

2 Responses

Can we say that products demands increase each year, so production must satisfy it and as a consequence, the production rate increase. If true, production capacity, dangerous products inventories increase too and associated risks increase globally. Even though the risk management methods, technologies, standards, etc., really improve it has not been enough. Anthony Spurgin mentioned in 2010 that the human reliability would be 60 to 80% of total probability of the catastrophic accidents. Based on that, mechanical integrity, probability of failures of materials and technologies can’t impact or reduce the probability of failure no more than 20 to 40%. Then, only the human behavior would significantly impact the rate of accidents. But human reliability is quite different to material reliability because materials doesn’t change behaviors by own decisions like humans. This is matter of behavior science and not materials behavior. Am I right?

Wilmer – that’s an interesting question. Human factors is always a contributing factor but that should be the start of investigation not a finding.

From what I can tell the incident rate has stayed comparable in the last ten years.