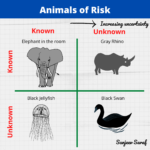

There is a big difference between proactively mitigating risks vs. reacting to incidents. Why do corporations wait to take active safety measures till an incident occurs? Because being proactive is hard…very hard and requires a lot of discipline.

Let me share a personal experience.

After my health check up a few years ago, the doctor told me that my cholesterol levels were significantly higher than normal. I was pretty shocked to learn that if my cholesterol levels do not come down in the next few months I will have go on medicine. This was even more shocking because I was 26! After that I cut down on red meat and also started exercising regularly.

Organizational Behavior

An organization’s approach to risk is no different than mine. The behavior towards safety changes in light of an event that can VISIBLY lead to damaging consequences.

In my case the event was high cholesterol levels and consequences were future health problems. In the case of organizations the behavior-changing events are incidents. One does not have to look beyond Bhopal to see how a major accident has impacted our approach to process safety. Hopefully, organizations have started learning from near-misses and not wait for catastrophes.

So, are you going to be proactive about your organization’s safety? Or are you going to wait till your health checkup alarms you?

5 Responses

So maybe combustible dust related fires, precursors to dust explosions are analogous to high cholesterol levels. Yet the majority of the time no protective action is taken concerning repeatable combustible dust fires in the manufactruing sector. The future dust explosion would be like having a massive heart attack.

John…realize that a dust explosion (or for that matter even dust fire) is a lagging indicator. Does the management have the discipline to put risk mitigation measures in place when everything is going fine?

I don’t think it’s so much the discipline but the added cost in implementing mitigation measures. Until there is a uniform regulatory framework which puts all manufacturers on the same playing field, then nothing will change. Sort of like the carrot on the stick, where increased regulatory enforcement and inspection activities will require all to implement layers of protection when everything is going fine.

A positive change of attitude occurred after the Imperial Sugar Refinery explosion in Feb 2008. The facility has now incorporated proactive administrative controls and RAGAGEP beyond the minimal regulatory requirements concerning combustible dust hazards

Dr. Saraf,

Good analogy. And you are right, a fire or deflagration IS a lagging indicator. I see this many times, a company will implement safety systems and procedures after an incident, while they may even have had similar incidences in the past. Many of these plants have signs with slogans preaching safety, but I see allot of combustible dust on floors, trusses, walls and machinery when touring these plants. I am always looking for the nearest fire extinguishers and exits when touring these plants! Employees have even told me they have heard muffled booms or smelled smoke in the past but could never pin-point where it originated.

John has a good point that some companies and industries are slow to implement safety systems until insurance companies or regulatory agencies force them to. It depends on the corporate safety culture, starting from the top down.

By the way, how is your cholesterol? I had a similar experience a couple years ago. Also add oatmeal, red rice yeast and CoQ10 to your diet, as needed.

It is always a less costly alternative and the best medicine to have the discipline to put risk mitigation measures in place before an incident!

-Jeff Nichols http://industrialfireprevention.blogspot.com/

Being pro-active when it comes to safety only makes sense. Making changes only after an emergency has happened doesn’t make sense. Lori