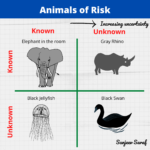

An existing equipment in a refinery may display flaws/damages that either existed during manufacturing or were induced during service. Let us briefly look at pre-service flaws and service-induced deterioration.

Pre-Service Flaws

Equipment flaws from pre-service lifetime are often discovered during in-service inspection because in-service inspection techniques are much detailed than during original construction. Typical pre-service flaws are:

- Material production flaws

- Welding related flaws

- Fabrication related flaws

- Heat treatment related flaw

In-Service Deterioration

Typically, following damages are seen in in-service refinery equipment:

- General and local metal loss due to corrosion and/or erosion

- Surface connected cracking (SCC)

- Subsurface cracking

- Microfissuring/microvoid formation

- Metallurgical changes

During fitness-for-service assessments it is important to determine the cause of damages so that to understand potential future degradation. Based on the understanding of the degradation mechanism necessary mitigation measures can be put in place.