Last year, the Government Accountability Office (GAO) reported that the Chemical Safety Board (CSB) is not meeting its statutory mandate by investigating major chemical accidents.

CSB’s Statutory Mandate

The Clean Air Amendment Act (CAAA) of 1990 directs CSB to

(1) investigate and report on the cause or probable cause of any accidental chemical releases from stationary sources resulting in a fatality, serious injury, or substantial property damages;

(2) make recommendations to reduce the likelihood or consequences of accidental chemical releases and propose corrective measures; and

(3) establish regulations for reporting accidental releases

In fairness, CSB is limited by resources (budget and number of investigators). In 2007, there were 920 incidents and it is not realistic to expect that the CSB can investigate all these incidents with a budget of $10-million and limited resources. CSB investigated five of these incidents and did not meet its statutory mandate of investigating all major incidents.

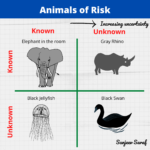

Before discussing CSB’s budget or strategy, I would like to revisit CSB’s statutory mandate from the perspective of preventing incidents in the future. Will investigating every major incident indeed help accident prevention in the future?

CSB Is Not the CSI of Chemical Industry

Everyone agrees that the main objective of CSB is to reduce chemical accidents in the future. Presumably CSB is achieving this goal of accident prevention by:

- Identifying learning from the incidents it investigates.

- Educating manufactures and regulators on these learning to avoid similar errors in the future

If you agree with the above, then CSB does not have to investigate all the incidents. CSB can focus on incidents that represent opportunity for the MOST learning. By investigating enough representative incidents, the safety board can now reach meaningful conclusions on preventing certain category of accidents.

Rather than focusing on CSB’s statutory mandate or budget, more relevant questions for meeting CSB’s objectives of accident prevention are:

- Can CSB justify the accidents it plans to investigate based on “learning potential”? What are CSB’s criteria for screening incidents for investigation?

- What accident model is being used by CSB to “learn” from incidents?

- How is the knowledge from incident investigations converted to future accident prevention strategies?

Merely increasing CSB’s budget is not a complete solution.

Consider this, how has the information generated from CSB investigations benefited the process industries? Can CSB confirm any incidents that have been prevented as a result of its investigation insights?

Don’t get me wrong I would much rather see money being spent on CSB than on Government motors…but I believe a careful evaluation of CSB’s objectives is needed for judiciously deciding the next steps.

3 Responses

The CSB is a complete joke. They are complete caught up in bureaucratic nonsense and inept. I have consistently seen them allow the RP to investigate themselves in order to save money. However, when there is an accident in a “fun” place, the CSB does not hesitate to fly 10 people out to have a look. The GAO report should be followed and the CSB needs to be dissolved now. Chemical accident investigation should be transferred to OSHA who at least has personnel and technical capabilities. All the CSB accomplishes is flying inept bureaucrats around the nation on the taxpayers’ dime.

Re the initial article. CSB does a very valuable job globally in investigating the incidents it does. It publishes more information on accidents and learnings from recent PS accidents than any other national body (US & non US)

Resources prevent it investigating more incidents. Then again, Industry has yet to show it can learn and implement all the lessons from each incident CSB have investigated.

Its not the job of CSB to “convert knowledge from incident investigations into to future accident prevention strategies?”. Isn’t that the role of another national body?

Re Mr Thomas’ comments above … don’t think they hold water… quite a few incidents investigated in places which are well off the beaten track of holiday makers and funseekers.

As an outsider looking in to your country, if OSHA were able to demonstrate the same focus and drive to reducing the losses (human & financial) from PS incidents to as low as is reasonably practicable as CSB then I believe high hazard US process plant & their neighbouring communities US would be safer places.

The CSB accident investigation process is a great model in providing lessons learned in the prevention of future accidents. Yet during the recommendation process there needs to be more transparency, collaboration and peer review between trade associations, professional organizations, industry, and a myriad of other stakeholders.

A good example would be the 2006 CSB Dust Hazard Study, which provided the foundation for the 2008 Combustible Dust bill, 2007 OSHA Dust NEP, and now OSHA ComDust rulemaking. The report in .pdf form was fantastic. Yet the data of 281 incidents from 1980-2005 in the Excel spreadsheet was a dismal attempt in providing stakeholders an appropiate picture of the probability of occurrence for essential risk analysis in policy-making.

In 2008, through media accounts, there was over 150+ combustible dust related fires and explosions in the manufactruing, non-manufactruing, and utility sectors. Yet in stark contrast, the $300,000 CSB Dust Hazard Study accounts for an average of 12 ComDust incidents annually.

It’s difficult to grasp that so much financial resources was dedicated to such underreporting . This frustration is compounded when one realizes that a only a handful of career governmental employees are directing occupational health and safety policy for an entire nation without essential and much needed EHS peer review and input.

Reminds me of the classic 1939 movie,the Wizard of OZ, with the The Wizard pulling the levers behind the screen creating all the smoke and thunder with the rest of the cast trembling. It’s not until Dorothy’s dog Toto, through curiosity pulls back the curtain and reveals that Wizard is not a wizard after-all, but Professor Marvel. Without peer review, transparency, and collaboration; stakeholders and the public cannot make informed decisions in the policy making process.