Pascagoula gas plant receives condensate from offshore Gulf of Mexico.

For separating components at cryogenic temperatures, it used brazed aluminum heat exchangers. These exchanger are susceptible to thermal fatigue due to low temperaures.

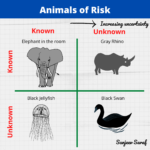

Take a look at the following timeline of how events influenced HAZOP and defects remained in the field.

1997 (design-stage): The HAZOP team identified potential damage mechanism to heat exchangers from thermal shock.

1998-99: Two gas trains commissioned for startup.

2007: There was a leak from one of the exchangers on Train B. It was fixed by welding.

2008: Leak from exchanger on Train A

2009 PHA Revalidation

The consequence of failure was deemed to be injury. The team recommended replacement of the aluminum heat exchangers.

2010: Two leaks, Train B.

2011: Leak, Train A.

2012: Leak, Train B.

2013 PHA Revalidation

Safety consequence was no longer identified from leak scenario. Instead, the team listed potential consequences that reflected plant's experience: a leak that can be repaired!

2014: Leak in Train B.

2015: Leak in Train B.

2016 incident

–Operators initiating controlled shutdown. Fire and explosion reported.

– Brazed aluminum heat exchanger (BAHX) failure from thermal fatigue

–13 different ruptures of piping and equipment during the course of the incident

–Community evacuation

Slides summarize the incident. (Source: Chemical safety board report)