Methane being extremely flammable, the fire and gas detection (FGD) system in LNG facilities should be capable of early detection of flammable gas leading to shutdown/isolation and depressurization.

Usually catalytic combustion type gas sensors are used for detecting LNG vapors; however, for these combustion gas sensors to work the vapors within flammable range have to reach the gas sensor and by then the release may have already spread within the facility. Therefore, LNG facilities should consider Ultrasonic gas detectors – these detect hydrocarbon gas leaks by sensing the distinct high frequency acoustic ultrasound emitted by all high-pressure gas leaks.

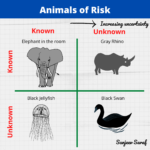

While ultrasonic sensors provide early detection of leaks, they are unable to distinguish the ultrasonic activity generated from other spurious noise that is generated by mechanical equipment in close proximity.

To systematically devise a fire and gas detection system for a LNG facility, we recommend considering the following performance characteristics for the detection system:

- Area Covered

- Response time

- Reliability

- Cost

7 Responses

Having helped clients and customers select and apply fire and gas detection instrumentation for more than a dozen LNG facilities and having participated in LNG leak detection research for more than four years, I understand that the selection criteria can’t be conveyed in a few short paragraphs.

Having said that, some of the most common detection technologies and important selection criteria are not mentioned above. There is much to consider but there are also many resources with specific LNG experience available.

Hi Ray…this post is specifically targeted at high-pressure releases and use of ultrasound.

Hi Saraf,

Understand that I Ultrasonic type will only detect the gas, not liquid. LNG will consider as liquid that might be not generate enought ultrasonic sound when it get leaks. Therefore what is the specific application of ultrasonic gas detector in the LNG Plant?

Hi Tanding…the specific use of ultrasonic detectors is for high pressure releases. For example, in a LNG regasification terminal there are places where high pressure natural gas release can occur.

Hey Dr. Saraf,

Our customers frequently ask us for recommendations on gas detectors, are there some ultrasonic detector manufacturers you’d recommend? Also, how often do they need maintenance/calibration?

Thanks,

James

Great info on the gas detectors!

Thanks for sharing this.

The use of pellistor sensors for flammable gas detection on any facility should be as a last choice where no other sensors are suitable (eg. for H2 detection). The pellistor sensor operation relies upon the availability of oxygen for the flammable gas to combust at the sensor in a stoichiometric ratio. If the flammable gas has rapidly flooded the atmosphere above the LEL (LFL) then the pellistor sensors will not operate. A better technology is infrared; either point or open path. However this technology type is now being replaced by open path laser gas detection which is able to indicate the presence of methane as low as a few ppm. This gives operators greater time to identify and respond to an event. A good detection combination is acoustic to indicate a gas leak and open path laser to confirm and locate gas presence.